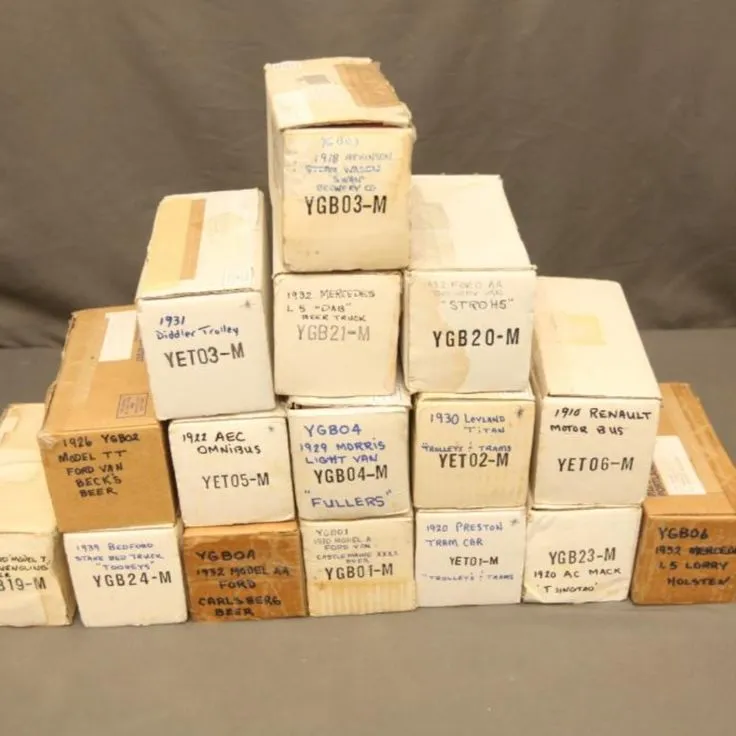

The Metal Marvels of Diecast Cars

Diecast cars are more than just toys; they are miniature works of art, intricate replicas that capture the essence of automotive design and history. The materials used to create these detailed models are a critical aspect of their quality, durability, and aesthetic appeal. Understanding the metals and other substances that go into diecast cars provides a deeper appreciation for the craftsmanship and engineering involved. This article explores the top materials that make up these beloved collectibles, detailing their properties, uses, and why they are chosen by manufacturers to bring these miniature vehicles to life. From the stalwart zinc alloy to the sleek aluminum, each material contributes to the charm and longevity of diecast cars.

Zinc Alloy The Backbone

Zinc alloy is the primary material used in the majority of diecast car production. It’s a versatile metal that provides an excellent balance of properties, making it ideal for creating detailed and durable models. Commonly referred to as Zamak, a term derived from the initials of the metals it’s composed of: zinc, aluminum, magnesium, and copper, zinc alloy is the go-to choice for the die-casting process because it is cost-effective and delivers quality. It is the foundation upon which many iconic diecast cars are built, allowing for the intricate designs and robust construction that collectors and enthusiasts cherish.

Properties of Zinc Alloy

Zinc alloy boasts several key properties that make it perfect for diecast car manufacturing. It has a low melting point, which is crucial for die-casting, as it allows the metal to be melted and injected into molds efficiently. It has high fluidity when molten, permitting it to fill the intricate details of the car molds. Zinc alloy offers excellent dimensional stability, so the cars maintain their shape and size over time. It also has good mechanical properties, including strength and hardness, making it resilient to wear and tear.

Why Zinc Alloy is Preferred

The popularity of zinc alloy stems from its ability to capture fine details, resist corrosion when properly treated, and its relatively low cost. The material is also easily painted and finished, allowing manufacturers to create a wide variety of colors and designs. The high production rate and relatively low cost of zinc alloy mean manufacturers can produce diecast cars affordably without sacrificing quality. This combination has made zinc alloy the preferred metal for diecast cars for many decades.

Steel Strength and Durability

Steel is another important material in diecast car construction, often used to reinforce specific components or enhance overall durability. While not as prevalent as zinc alloy, steel plays a crucial role in ensuring the structural integrity and longevity of diecast models. Known for its superior strength and resistance to wear, steel components contribute to the robustness and detailed construction of these miniature vehicles.

Uses of Steel in Diecast Cars

Steel is commonly utilized in the axles, springs, and sometimes chassis components of diecast cars. These parts require strength and the ability to withstand the stress of movement and handling. Steel ensures the wheels turn smoothly, the suspension functions properly, and the overall car withstands impacts and play. Steel is also often used for smaller details, such as screws and pins, that secure the parts together.

Advantages of Steel

The primary advantages of using steel are its strength and durability. Steel components can withstand significant forces, preventing breakage and extending the lifespan of the diecast car. Steel is also highly resistant to wear and tear, ensuring that moving parts function correctly for years. Furthermore, steel can be precisely manufactured, allowing for the creation of complex and precise components.

Aluminum Lightweight Powerhouse

Aluminum is a metal frequently employed in higher-end diecast car models. Its use enhances the overall quality and often adds to the collectibility of a particular model. Known for its light weight, high strength-to-weight ratio, and excellent corrosion resistance, aluminum provides manufacturers with advantages that translate to premium-quality models.

Aluminum in High-End Models

Aluminum is often incorporated into the chassis, engine components, and body panels of high-end diecast cars. The metal’s ability to precisely replicate details makes it ideal for creating complex designs. Using aluminum elevates the perceived value and quality of the model, often appealing to serious collectors. The lighter weight can also impact playability, making the cars more responsive to movement and handling.

Benefits of Using Aluminum

Aluminum provides several key benefits in diecast car manufacturing. Its lightweight nature helps in creating models that are easy to handle and maneuver. The high strength-to-weight ratio provides durability without adding excessive mass. Aluminum is naturally resistant to corrosion, which means the models can withstand environmental conditions for extended periods. It also offers excellent surface finish qualities, allowing for detailed paint applications and other aesthetic enhancements.

Other Metals in the Mix

In addition to the primary metals, diecast cars incorporate various other materials, each serving a unique purpose in the design and functionality. These additional metals add to the complexity and realism of the models, helping to make them as accurate as possible.

Tin Usage and its Role

Tin may be used in the form of solder in certain applications to join metal parts together, and it is not often used as a structural element on its own. Tin’s low melting point and malleability make it an effective material for creating strong, secure bonds within the diecast car.

Copper Details and Applications

Copper is frequently incorporated into diecast cars for specific decorative and functional purposes. It’s often utilized in the creation of detailed parts, like engine components, exhaust systems, and interior details. Copper’s malleability allows for precision detailing, while its electrical conductivity makes it ideal for certain electrical components if the model includes functional features. The distinctive reddish-brown color adds an element of visual appeal, enhancing the model’s realism.

Brass Adding Premium Finishes

Brass, an alloy of copper and zinc, is sometimes used to create premium finishes and details. The bright, golden appearance of brass makes it a favored material for trim pieces, emblems, and other decorative elements. Brass also offers corrosion resistance and durability, which are desirable qualities for components that face wear and exposure to the elements.

Plastics and Resins The Supporting Cast

Beyond the metals, plastics and resins are essential components of diecast cars. These materials are used for various purposes, from creating realistic interiors to designing functional parts, such as tires and windows. These non-metallic materials complement the metal elements, enhancing the overall detail and functionality of the miniature vehicles.

Types of Plastics Used

Various types of plastics are employed in diecast car manufacturing. ABS (Acrylonitrile Butadiene Styrene) is a common choice for interior parts, dashboards, and other detailed components. PVC (Polyvinyl Chloride) may be used for windows and other transparent elements. Thermoplastic elastomers (TPEs) are often used for creating tires and other flexible parts. Each plastic is selected for its particular properties, such as flexibility, durability, or transparency, to meet specific design and functional requirements.

Why Plastics are Essential

Plastics are vital in diecast car design due to their versatility, flexibility, and cost-effectiveness. They can be molded into complex shapes, making it possible to recreate the intricate details of car interiors, exterior components, and functional parts. Plastics are typically lighter than metals, contributing to the overall weight of the models, while providing excellent impact resistance. The lower cost of plastics also helps in keeping diecast cars affordable.

The Manufacturing Process Unveiled

The production of diecast cars is a fascinating process, blending precision engineering with artistic detail. The manufacturing process typically involves several key stages, from the initial design and mold creation to the final assembly and finishing touches. Understanding these stages helps appreciate the work that goes into each miniature car.

Die-Casting Technique Explained

The die-casting process is the core method of manufacturing the metal parts of diecast cars. The process involves injecting molten metal, usually zinc alloy, into a mold under high pressure. The molds are typically made of steel and are precisely designed to capture the intricate details of the car’s body and components. Once the metal cools and solidifies, the molds are opened, and the metal castings are removed. The precision and speed of die-casting allow for mass production of complex metal parts.

Finishing Touches and Details

After the die-casting process, the individual parts of the diecast car go through a series of finishing steps. These include removing any excess material, polishing surfaces, and preparing the parts for painting. Paint applications are typically done with precision, often using multiple coats and detailed designs to match the real-life vehicle. The final steps involve assembling the various components, adding decals, and attaching the wheels, tires, and other finishing details. Each step is carefully executed to ensure the final product meets the high standards of quality and realism.

Conclusion A Legacy of Metal and Miniature Craftsmanship

The materials used in diecast cars are more than just components; they are the essence of the miniature vehicles that have captured the hearts of collectors and enthusiasts worldwide. From the sturdy zinc alloy to the elegant aluminum, each material brings its unique properties to the table, enhancing the appearance, durability, and overall appeal of these cherished models. As the diecast car industry continues to evolve, with new materials and manufacturing techniques being innovated, the legacy of metal and miniature craftsmanship will endure, offering an engaging and exciting experience to everyone.