Top 7 Secrets of Diecast Model Makers

Diecast model making is a fascinating blend of art, engineering, and meticulous craftsmanship. Behind every stunning miniature car, plane, or vehicle lies a wealth of knowledge and skill. This article peels back the curtain, revealing the top 7 secrets that separate the amateurs from the expert diecast model makers. These secrets encompass everything from initial planning and material selection to the intricate processes of die-casting, finishing, and presentation. By understanding these key elements, enthusiasts and aspiring model makers alike can elevate their skills and create truly remarkable miniature masterpieces.

The Importance of Research and Planning

Before a single speck of metal is touched, successful diecast model makers invest significant time in research and planning. This initial phase involves a deep dive into the subject matter. Understanding the vehicle’s history, original design, and specific features is crucial for accuracy. This may involve studying original blueprints, photographs, and even visiting museums or examining real-world examples. Thorough research informs all subsequent decisions, from material selection to detailing. Planning also includes creating detailed schematics and deciding on the scale of the model. A well-defined plan acts as the roadmap, ensuring a cohesive and accurate final product. For diecast model makers, failing to plan is planning to fail.

Choosing the Right Materials

The selection of appropriate materials is paramount for both the aesthetic and structural integrity of a diecast model. The primary material is, of course, the die-cast metal, which is typically a zinc alloy, but the specifics can vary depending on the desired properties and the manufacturer’s preferences. Beyond the metal, the model maker must consider the other materials needed. These include paints, primers, adhesives, and decal materials. The choice of materials can influence the final look of the model, and must be carefully researched. High-quality materials are an investment that directly impacts the model’s realism, durability, and value. For example, using high-quality paints that are resistant to fading and chipping is a critical aspect of achieving a long-lasting and impressive finish.

Metal Alloys for Diecast Models

The core material used by diecast model makers is usually a zinc alloy, often referred to as Zamak. Zamak alloys are favored because of their excellent casting characteristics, ability to capture fine details, and relatively low melting point. Other metals, such as aluminum or tin, may be added to the alloy to adjust specific properties like strength or corrosion resistance. Diecast model makers understand that the composition of the metal alloy impacts everything from the model’s weight and feel to its ability to hold intricate details during the casting process. Careful alloy selection is an important factor. The choice of alloy greatly impacts the final quality and longevity of the model, guaranteeing a durable and beautiful finished product.

The Die-Casting Process

Die-casting is the heart of the diecast model making process. It involves injecting molten metal under high pressure into a mold, known as a die. This mold is typically made of steel and is precisely engineered to create the shape of the model. The molten metal quickly solidifies within the mold, taking the shape of the model. The speed and pressure of the injection are carefully controlled to ensure that the metal fills every intricate detail of the mold. Skilled diecast model makers have a deep understanding of the die-casting process, including factors such as temperature, pressure, and cooling rates, to achieve optimal results. This is the process that allows for the mass production of high-detail models.

Mold Design and Creation

The mold is the most crucial element in the die-casting process. Its design dictates the model’s final appearance. Mold design is a complex undertaking. The design must account for the model’s intricate details, the metal’s flow during injection, and the ejection of the finished part. Diecast model makers use advanced software to design these molds with a high degree of precision. The mold itself is typically manufactured from hardened steel. Creating the mold is a time-consuming process that requires specialized equipment and expertise, which is why the molds are so expensive to make. The quality of the mold directly impacts the final model’s accuracy and the level of detail that can be achieved. A well-designed and expertly crafted mold is essential to the diecast model making process.

Injection and Cooling

Once the mold is ready, molten metal is injected into it under high pressure. This forces the metal to fill every nook and cranny of the mold. The speed and pressure of injection are precisely controlled to ensure that the metal completely fills the mold, capturing the finest details. After injection, the metal must cool and solidify within the mold. The cooling process is critical, as uneven cooling can lead to defects such as warping or shrinkage. Diecast model makers carefully manage the cooling process to ensure uniform cooling. The time required for cooling depends on the size and complexity of the model. Careful management of injection and cooling is necessary to ensure high-quality models.

Finishing and Detailing Techniques

After the die-casting process, the model undergoes a series of finishing and detailing steps. These steps refine the model’s appearance and remove any imperfections that may have resulted from the casting process. This includes removing any flashing, which is excess metal that forms at the mold’s parting lines. Sanding, polishing, and other surface treatments are then used to prepare the model for painting. Detailed detailing involves adding intricate features to enhance the model’s realism. This can include adding separate parts, such as mirrors, door handles, and lights, or etching fine details into the metal surfaces. The level of detail is what transforms a diecast model from a simple toy into a work of art. This step also allows the model maker to show their true skills.

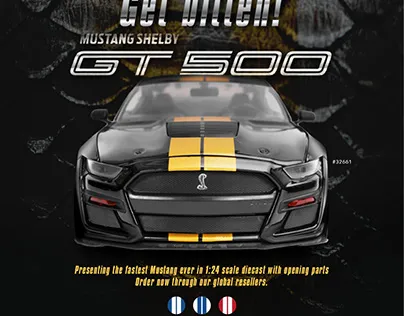

Painting and Decals Application

Painting is a critical step in the diecast model making process, as it brings the model to life and determines its final appearance. The model makers must carefully prepare the surface to ensure that the paint adheres properly. This usually involves priming the model to create a smooth and uniform surface. The application of paint requires considerable skill. Model makers often use airbrushes to apply paint in thin, even coats, building up the color gradually. Decals, which are essentially miniature stickers, are applied to add details such as logos, markings, and stripes. The application of decals requires precision and patience, as they must be perfectly aligned to achieve a realistic look. Clear coats are applied to protect the paint and decals and provide a glossy finish.

Assembly and Quality Control

Once the painting and detailing are complete, the model is assembled. This involves attaching the various components, such as the wheels, axles, and interior details. The assembly process requires precision and attention to detail, as each part must fit perfectly to ensure that the model is structurally sound and visually appealing. Quality control is essential throughout the entire process. Skilled diecast model makers meticulously inspect each model at every stage, ensuring that it meets the highest standards of quality. Any defects or imperfections are addressed before the model is packaged. Quality control ensures that each model is a perfect replica of the original vehicle.

Packaging and Presentation

The final step in the diecast model making process is packaging and presentation. The packaging should protect the model during shipping and storage and also add to its value and appeal. Many diecast models are presented in attractive boxes that include details about the model. Packaging can include custom display stands or other accessories that enhance the model’s presentation. Diecast model makers often design packaging that reflects the model’s theme. A well-designed package will enhance the overall experience for the collector. Careful packaging can help the model stay protected over a long period of time, as well.

Where to Find Information and Inspiration

The world of diecast model making is vast and full of resources for those eager to learn and improve their craft. Model makers have access to a plethora of sources of information and inspiration. Online forums and communities bring together model makers of all skill levels, offering opportunities to share knowledge, seek advice, and showcase their work. Museums often display collections of diecast models, providing inspiration and insights into various techniques. Books and magazines dedicated to model making offer detailed tutorials, reviews of materials and tools, and interviews with experienced model makers. Attending model shows and conventions is an excellent way to connect with other enthusiasts and to view a wide array of models.

In conclusion, the creation of diecast models is a complex and rewarding art. The secrets to making amazing models come down to mastering planning, choosing the right materials, carefully executing the die-casting process, skillfully detailing, and presenting the final product beautifully. By understanding and applying these principles, aspiring diecast model makers can achieve impressive results and enjoy this fascinating hobby. The journey into the world of diecast models is not only a journey into miniature engineering, but also a testament to the beauty of meticulous craftsmanship. As you embark on this creative path, keep these secrets in mind. You’ll be well on your way to creating impressive models.